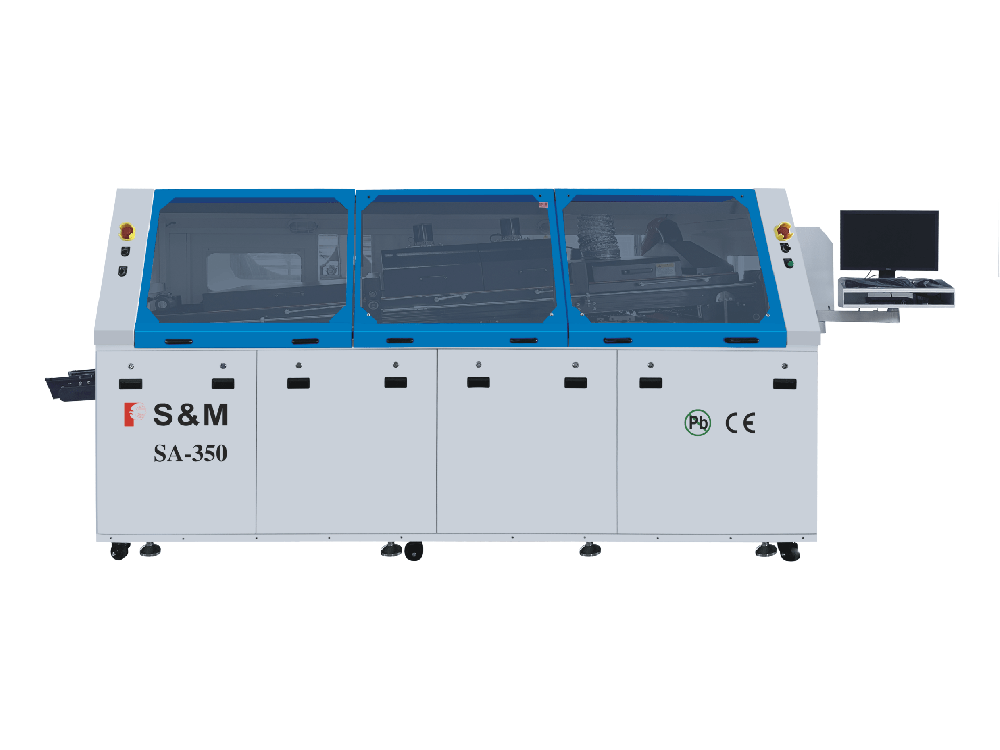

LEAD-FREE WAVE soldering

- The soldering area of lead-free wave soldering is a large-area soldering operation on the PBC substrate.

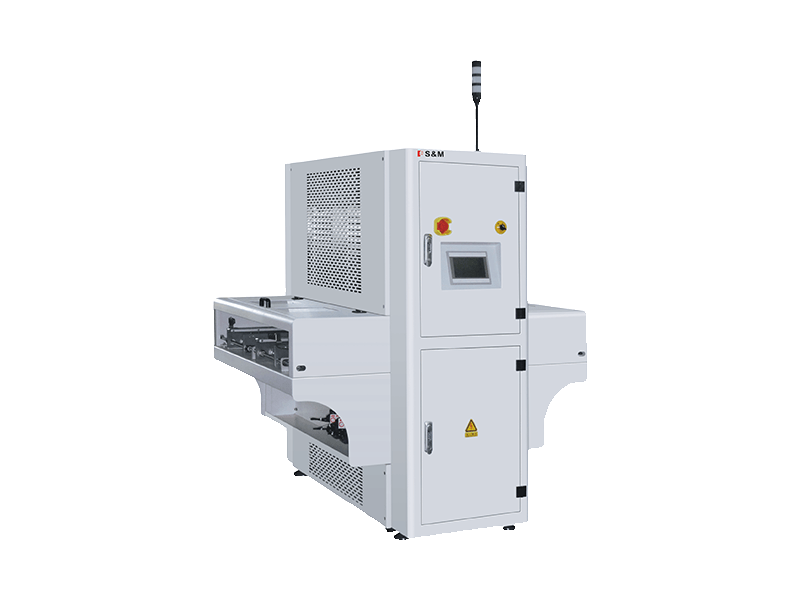

Vacuum reflow soldering

- Vacuum reflow soldering is the soldering of electronic components in a vacuum environment. Very low oxygen concentration can be achieved by providing a nitrogen filling device.

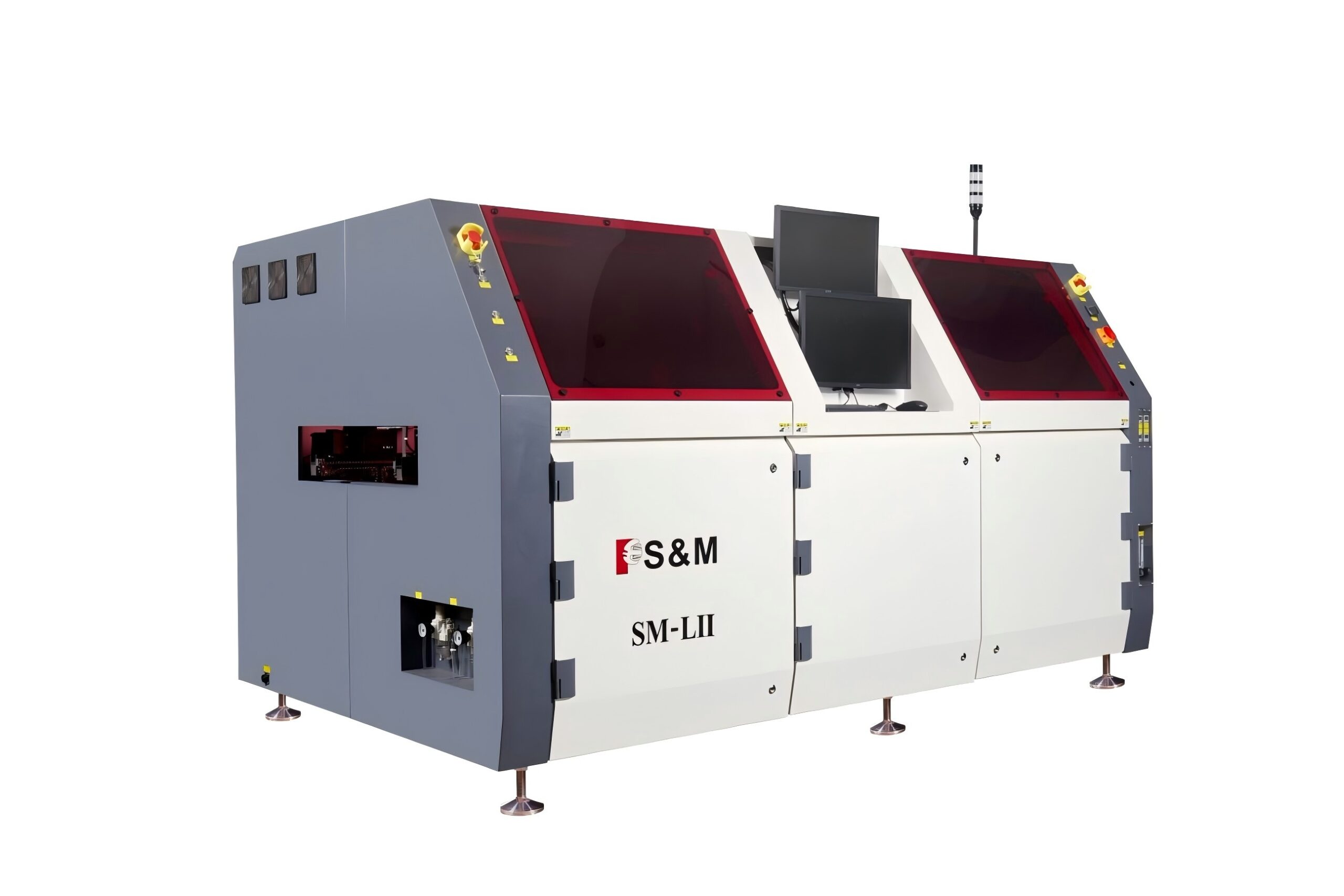

Selective wave soldering

- Selective wave soldering uses double soldering stations to perform fixed-point positioning soldering on the PCB substrate.

Full Productionlines Professional One Stop SMT Equipments Solution Manufacturer

S&M as a leading professional SMT electronic equipment manufacturer in China, offers a comprehensive range of equipment to support the SMT production process,such as reflow ovens, Nitrogen / Air Wave Solder, etc. to complete your SMT Line.

Work with the best

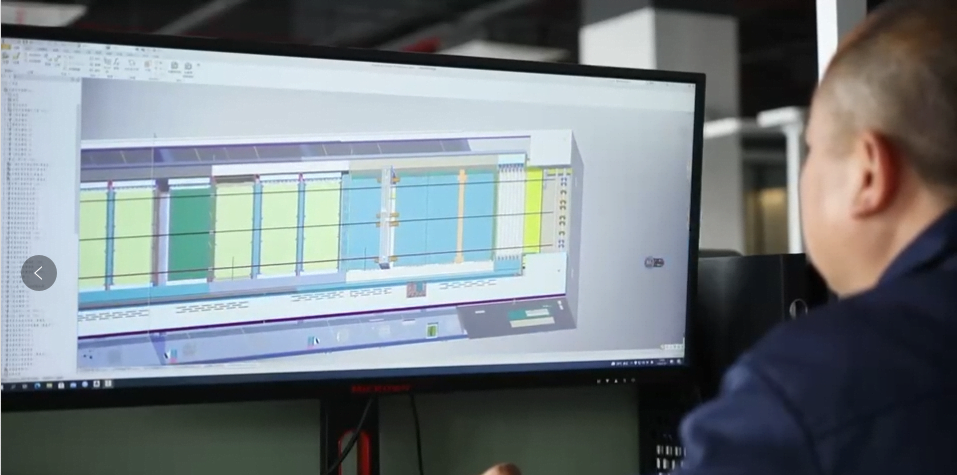

See our facilities for yourself

The only set of electronic components surface adhesive welding and intelligent transmission equipment development and manufacturing in one of the intelligent equipment suppliers — Shenzhen Chuxin Electronic Equipment Co., Ltd. was founded in 2000, registered trademark brand: S & M, Chinese brand: Sunandmountain, is a 100,000 square metres of independent intelligent industrial park, and is committed to becoming a leader in the electronic components surface adhesive welding equipment and intelligent transmission equipment industry. National high-tech enterprises won the Shenzhen ‘speciality, speciality and new small and medium-sized enterprises’ and ‘innovative small and medium-sized enterprises’ certification; business philosophy — sustained innovation, sustainable management.

SMT LINE SOLUTIONS

Provide the personalized solution according to the different SMT assembly demand

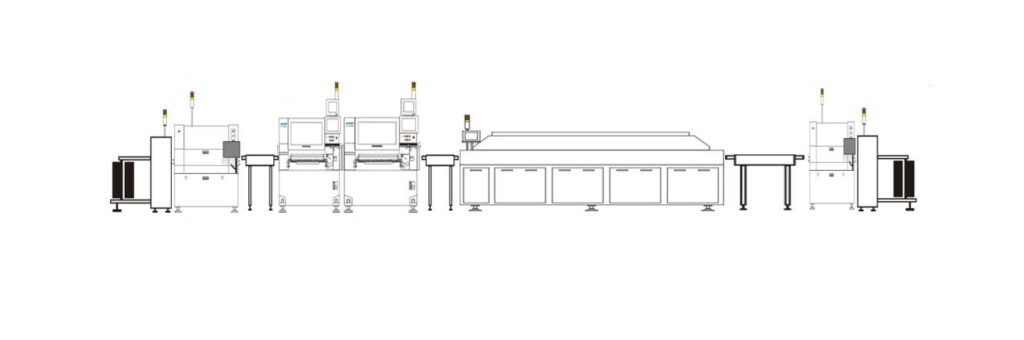

Side Entry Loader

Fully Automatic Printing Press

0.5m Single Track Conveyor

Hanwha SM471

0.5m Single Track Conveyor

8 zones Single Track Air Reflow Oven

Single Track Cooling Conveyor

Online Post-furnace AOI

Side Entry Unloader

LED

SMT LINE SOLUTIONS

Provide the personalized solution according to the different SMT assembly demand

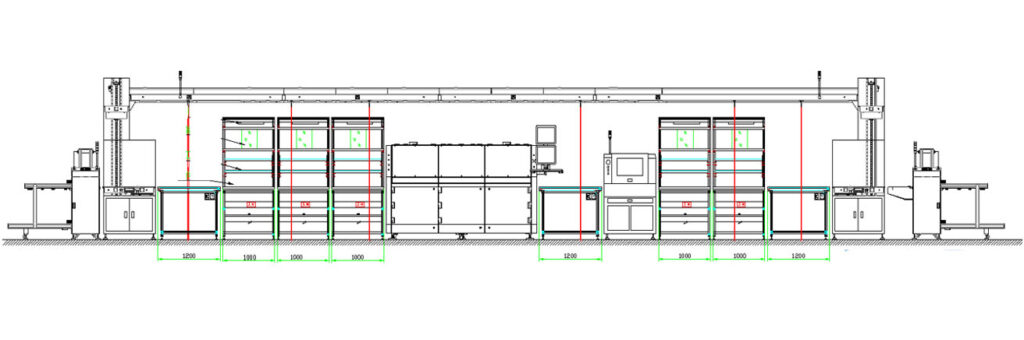

Triple-Frame Loader:

Three parallel material frames

PCB size: 50mm-250mm

AGV docking mode

PCB cleaning machine: Suitable for

SMT process cleaning needs

High flexibility

Conveyor: Durable, anti-static

conveyor belt

PCB size: 50mm to 460mm

Reflow Oven

Lead-free, hot air, multi-temperature zone

Conveyor system: single track/dual track

Air/nitrogen

Cooling conveyor;

With auxiliary cooling function

PCB size: 50mm~460mm

Single Station Shuttle Conveyor;

Versatile,with

flexible selection of

entry and exit

locations and directions

Buffer:Comprehensive

multi-function

Servo positioning system

Triple-frame PCB collector:

Three parallel racks

PCB size: 50mm-250mm

S&M Complete Line Solution Line

SMT LINE SOLUTIONS

Provide the personalized solution according to the different SMT assembly demand

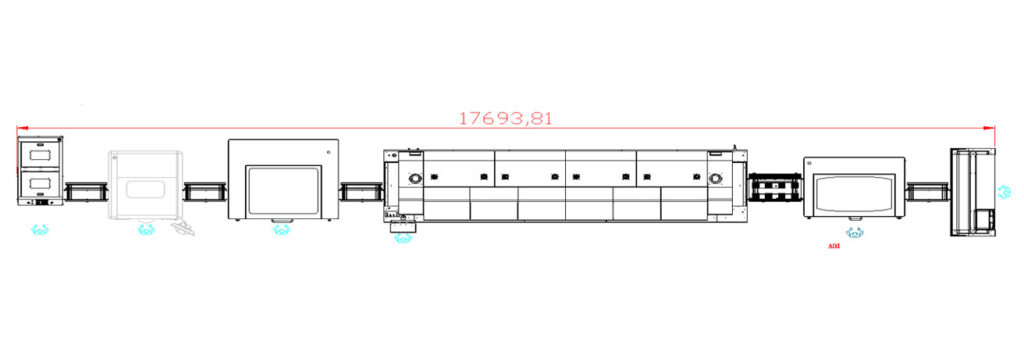

0.8m

Vacuu

m Bare

Loader

0.8m

Monorail

Docking

Station

Printing Machine

0.8m

Monorail

Docking

Station

Fast Smart

Modular

Mounter

0.8m

Monorail

Docking

Station

10 Zones Single

Rail Air Reflow Oven

1.0m

Monorail

Cooling

Docking

Station

AOI

0.8m

Monorail

Docking

Station

Plate

Removal

Workbench

Smart Display&MiniLED

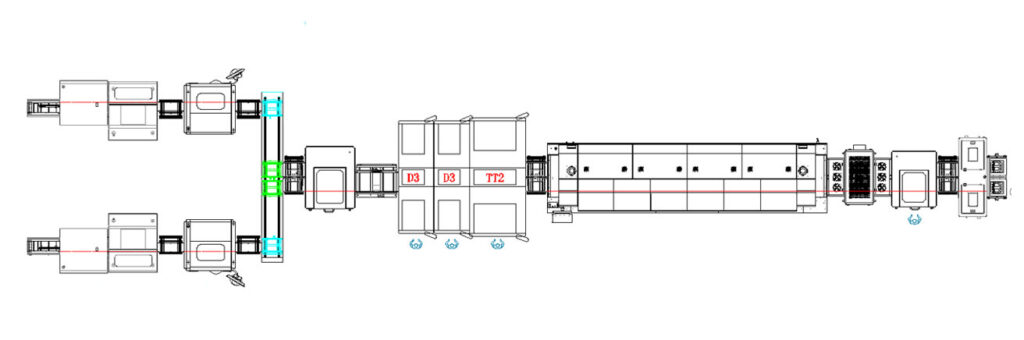

SMT LINE SOLUTIONS

Provide the personalized solution according to the different SMT assembly demand

Side

Entry

Loader

Lifting

Platform

Conveyor

1.0m Plug-in Line

Selective Wave Soldering

Conveyor

AOI

1.0m Welding Wire

Conceyor

Lifting Platform

Side Entry Unloader

New Energy Industry

SMT LINE SOLUTIONS

Provide the personalized solution according to the different SMT assembly demand

Suction Plate Machine 806#

Marking Machine

0.5m Conveyor

Printing Press

Dual Station Shuttle Conveyor

0.5m Conveyor

1.0m

Double-track

NG/OK

Conveyor

Dual-rail SPI

Dual

Station

Shuttle

Conveyor

Printing Press

0.5m Conveyor

0.5m Conveyor

Marking Machine

Suction Plate Machine 806#

SMT machine

0.5m Conveyor

Reflow Oven

Double-track Cooling Buffer

Online AOI

0.5m Conveyor

Double Frame

Double Track

NG/OK Unloader

Medical Device Industry

SMT production line is generally composed of the loader and unloader, Buffer, solder paste mixer, stencil printer, High-speed mounter, Coveryor, Reflow, automatic optical detector (AOI), and X-RAY detector according to customers’ needs.

S&M, one of the reliable SMT equipment suppliers/manufacturers, provides you cheap pick and place machine with high quality. If your company needs any SMT assembly line, please contact us!

Experienced Technicians

Our technical team boasts an average tenure of over 27 years with SMT industry, bringing a wealth of expertise and reliability to every project.

Efficient Troubleshooting

We pride ourselves on the swift diagnosis and resolution of equipment issues, minimizing downtime and maximizing your production efficiency.

Partnership

Select S&M for a seamless partnership that combines expertise, customization, and ongoing support,ensuring your team is equipped with the knowledge they need for success.

Flexible Service

Provide adaptable post-warranty support, tailored to your specific needs.ensuring that your equipment or an entire production line is ready to perform at its best.

SOME OF OUR PRESTIGIOUS CUSTOMERS

S&M has advanced lead-free process equipment industry standards since 1997.

Our engineers can fabricate complex technology that the others won't even try.

We have internationally renowned qualifications and certifications.

Domestic capital customers

Hongkong Macao and Taiwan customers

Foreign customors

WHAT OUR CUSTOMERS SAY

Our customers have said about how we fulfilled their requirements.

S&M'S Nitrogen / Air Wave Solder is Great!

Date of experience: April 06, 2024

Our No.1 source for Vertical Curing Oven!

Even for a complex full productionlines we got very good results from S&M. We did a lot of projects with S&M during the last 2 years and they always did an outstanding job – high quality (I can also recommend their Nitrogen / Air Wave Solder and PCB Link Conveyor), reliable, extremely fast and perfect communication. I highly appreciate working with Ruan and already recommended them to many of our partners.

Date of experience: November 07, 2023

Exceptional Lead Free Hot Air Reflow Oven at competitive price!

My experience with S&M has been nothing but exceptional. From the start the communication has even accurate and fast. Specificities of the customization that may meet production difficulties are promptly pointed out with suggested solutions. The price of Reflow Oven is competitive. And the QC of the final product is also excellent. There is no doubt that I will go back again

Date of experience: April 06, 2023

Great service, lead times, and quality of work!

The S&M team have become an invaluable supplier for our SMT Equipments Line Process. Their response time is quick, their prices and lead times are great, and the products I’ve received have been excellent.