Reflow soldering stands as a cornerstone in the assembly of printed circuit boards (PCBs). The quality of solder joints directly impacts the reliability and performance of electronic devices. Eindhoven, a hub for technological advancements, emphasizes the importance of solder quality. The Philips Centre for Manufacturing Technology in the Netherlands highlights nitrogen’s role in enhancing soldering processes. Nitrogen creates an inert atmosphere, reducing oxidation and improving joint strength. The Centre for Manufacturing Technology reports a significant reduction in defects. This advancement showcases the pivotal role of nitrogen in modern manufacturing.

Understanding Reflow Soldering

Basics of Reflow Soldering

Definition and Process Overview

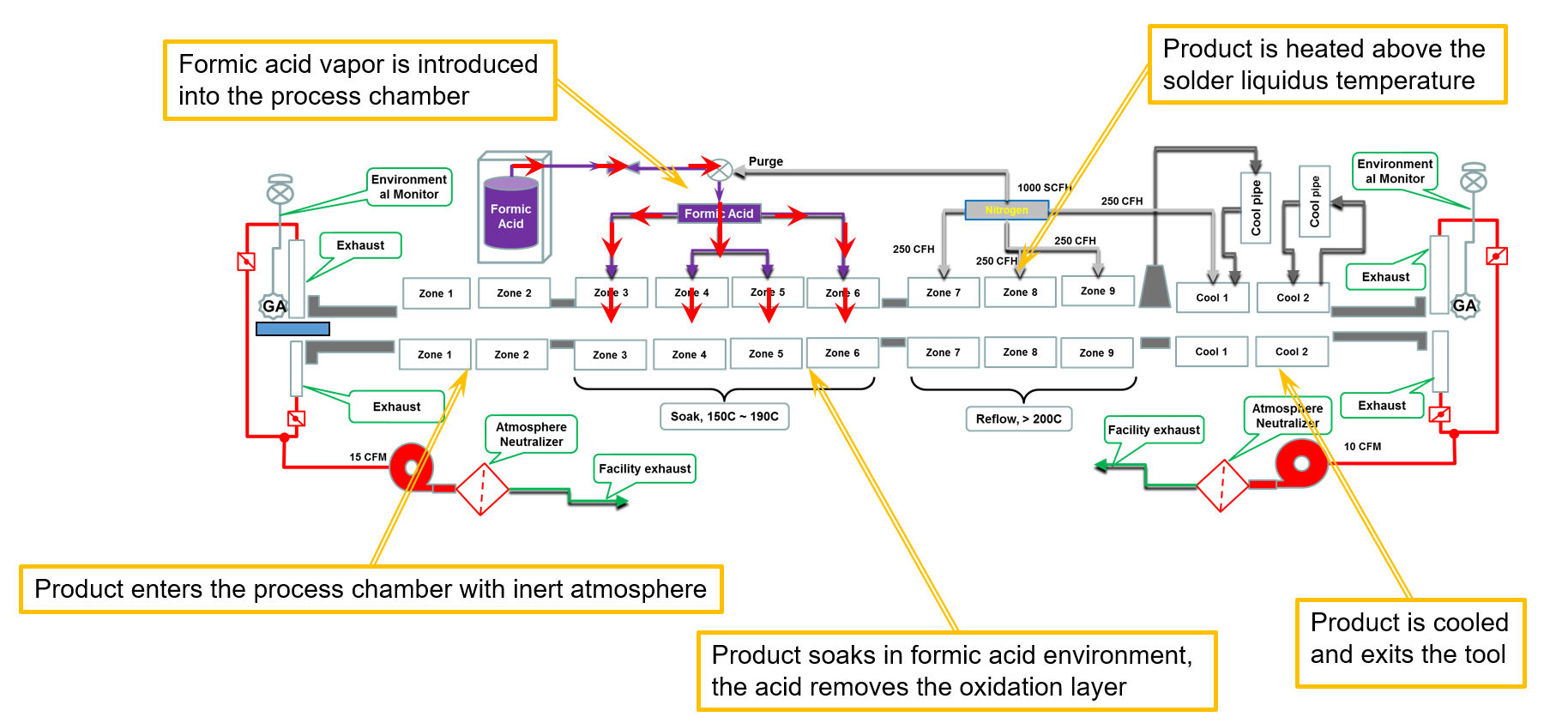

Reflow soldering is a critical process in the assembly of printed circuit boards (PCBs). The process involves heating solder paste to form reliable electrical connections between components and the PCB. The solder paste, a mixture of powdered solder and flux, gets applied to the PCB pads. Components are then placed on the board, and the assembly passes through a reflow oven. The oven heats the assembly to a temperature that melts the solder, creating solid joints upon cooling.

Key Components and Equipment

Key components in reflow soldering include the reflow oven, solder paste, and PCB. The reflow oven plays a crucial role by providing controlled heat to melt the solder paste. Different zones within the oven ensure gradual heating and cooling, preventing thermal shock to components. Solder paste quality affects joint strength and reliability. The PCB serves as the foundation for mounting electronic components, requiring precise alignment during the soldering process.

Challenges in Reflow Soldering

Common Defects and Issues

Reflow soldering can encounter several defects. Common issues include solder bridges, voids, and insufficient wetting. Solder bridges occur when excess solder creates unwanted connections between pads. Voids, or air pockets, weaken solder joints and affect electrical performance. Insufficient wetting results in poor adhesion between the solder and component leads, compromising joint integrity.

Factors Affecting Solder Quality

Several factors impact solder quality in reflow soldering. Temperature profiles within the reflow oven must be precisely controlled. Incorrect temperatures can lead to incomplete melting or overheating. The composition and application of solder paste also influence joint quality. Oxidation during the soldering process poses a significant challenge, affecting wetting and increasing defect rates. Nitrogen atmospheres in reflow ovens can mitigate oxidation, enhancing solder quality and reducing defects.

Scientific Research Findings:

- Research Findings on the Role of Nitrogen in Improving Solder Quality: Nitrogen improves solder joint quality by reducing oxidation and ensuring a clean surface for the solder to adhere to. This results in better wetting, stronger connections, and fewer defects.

- Influence of Nitrogen Atmosphere on Soldering Defects: A study by the University of Massachusetts found that a nitrogen atmosphere reduced the total defect rate by 95%.

Role of Nitrogen in Reflow Soldering

Why Use Nitrogen?

Reduction of Oxidation

Introducing Nitrogen into the reflow soldering process plays a crucial role in reducing oxidation. Oxidation occurs when oxygen interacts with the solder and PCB pads, leading to defects. The presence of Nitrogen creates an inert atmosphere inside the reflow oven. This environment limits oxygen levels to as low as 1000 ppm, significantly reducing oxidation risks. The reduction in oxidation ensures cleaner surfaces for soldering, enhancing the overall quality of the solder joints.

Improved Wetting and Flow

Nitrogen in Reflow Soldering enhances the wetting properties of the solder paste. Improved wetting results from the reduced oxidation environment created by Nitrogen. The solder flows more freely, covering the intended areas without forming voids or air pockets. This improvement leads to stronger and more reliable connections between components and the PCB. The enhanced flow of solder minimizes the occurrence of defects, contributing to consistent and high-quality solder joints.

Comparative Analysis: Nitrogen vs. Air

Solder Joint Quality

The use of Nitrogen versus air in reflow soldering shows significant differences in solder joint quality. Nitrogen reduces the occurrence of voids by promoting better solder flow and reducing air entrapment. Studies have shown that Nitrogen environments lead to stronger and more reliable joints. The absence of oxidation in Nitrogen atmospheres ensures that the solder and PCB pads remain clean, further enhancing solder joint quality.

Reliability and Longevity

Reliability studies and shear force examinations highlight the positive influence of Nitrogen on solder joint longevity. Nitrogen reflow soldering reduces the possibility of insufficient soldering and solder voids. The inert atmosphere prevents oxidation, ensuring good solder wetting. The reduced likelihood of solder voids contributes to the long-term reliability of electronic devices. The use of Nitrogen in reflow soldering provides a robust solution for achieving durable and dependable solder joints.

Benefits of Using Nitrogen

Enhanced Solder Quality

Reduction in Defects

Nitrogen plays a crucial role in reducing defects during the reflow soldering process. The inert atmosphere created by nitrogen minimizes oxidation, which is a primary cause of soldering defects. Studies have shown that implementing nitrogen can lead to a 30% reduction in defect rates. This significant decrease in defects ensures higher quality and reliability in electronic assemblies. The improved wetting characteristics of solder joints in a nitrogen atmosphere further contribute to the reduction of defects.

Consistency in Results

Consistency in soldering results is vital for maintaining high production standards. Nitrogen helps achieve this consistency by creating a stable environment that reduces variability in the soldering process. The use of nitrogen leads to uniform solder joint quality across different production batches. A study highlighted a 95% reduction in total defect rates when using nitrogen, demonstrating its effectiveness in ensuring consistent outcomes. The enhanced surface tension and reduced oxidation provided by nitrogen ensure that solder flows correctly, resulting in strong and reliable connections.

Cost-Benefit Analysis

Initial Investment vs. Long-term Savings

Investing in nitrogen systems for reflow soldering may require an initial financial outlay. However, the long-term savings and benefits outweigh these initial costs. The reduction in defects and rework leads to lower production costs over time. Nitrogen’s ability to improve solder joint quality also reduces the need for machine maintenance and rework. These factors contribute to significant cost savings in the long run, making nitrogen a cost-effective solution for manufacturers.

Impact on Production Efficiency

Nitrogen enhances production efficiency by streamlining the soldering process. The reduction in defects and rework translates to faster production cycles and increased throughput. Manufacturers experience fewer interruptions and delays, leading to more efficient use of resources. The improved solder joint quality achieved with nitrogen also reduces the need for post-soldering inspections and corrections. This efficiency boost allows manufacturers to meet production targets more effectively, enhancing overall productivity.

Experimental Results and Implications

Case Studies and Findings of Chuxin

Real-world Applications

Chuxin’s research highlights the practical applications of nitrogen in reflow soldering. Many industries, including automotive, medical, defense, and aerospace, benefit from nitrogen reflow for PCBA. Nitrogen enhances the reliability of electronic assemblies by reducing defects. Mo Ohady, General Manager at Digicom Electronics, emphasizes the importance of eliminating failures in devices. Nitrogen plays a crucial role in achieving this goal. Digicom Electronics implemented nitrogen in their manufacturing process to produce high-quality products. The use of nitrogen leads to a 50-60% reduction in defect levels.

Data and Statistics

Statistical data supports the effectiveness of nitrogen in reflow soldering. Studies reveal a significant decrease in defects when using nitrogen. A reduction of 95% in total defect rates demonstrates nitrogen’s impact. The inert atmosphere created by nitrogen minimizes oxidation, leading to cleaner solder joints. Amit Sahni highlights nitrogen’s role in improving solder joint quality. The enhanced wetting properties result in stronger connections between components and the PCB. These improvements contribute to the long-term reliability of electronic devices.

Implications for the Industry

Trends and Future Directions

The industry trends indicate a growing adoption of nitrogen in reflow soldering. Manufacturers recognize the benefits of nitrogen for high-end applications. PCBONLINE Team recommends nitrogen reflow for projects requiring superior quality. The demand for reliable electronic assemblies drives the need for nitrogen. The trend towards narrower pitch designs further emphasizes nitrogen’s importance. Nitrogen’s ability to reduce defects aligns with industry goals for high-quality production.

Recommendations for Implementation

Manufacturers should consider nitrogen reflow for PCBA to enhance product quality. The initial investment in nitrogen systems offers long-term savings. The reduction in defects and rework leads to lower production costs. Nitrogen improves production efficiency by streamlining the soldering process. Email communication with suppliers can facilitate the integration of nitrogen systems. Call to action for manufacturers: explore nitrogen’s benefits for improved soldering outcomes. The ISSN for industry publications provides valuable insights into nitrogen reflow practices. Downloads of technical guides offer practical implementation strategies. The March towards nitrogen adoption continues as manufacturers seek reliable solutions.

High Production Throughput with Nitrogen

Reflow Soldering for High Volume Production

Efficiency and Speed

Manufacturers seek High Production Throughput in modern electronics manufacturing. The ERSA Hotflow Nitrogen Reflow oven offers a solution. This equipment provides an inert atmosphere that enhances solder joint quality. Klein Wassink emphasizes the importance of this technology in achieving efficient production. The Hotflow Nitrogen Reflow oven maintains consistent temperature profiles. This consistency ensures uniform heating and cooling during the SMT reflow process.

Surface Mount Technology (SMT) benefits from nitrogen’s ability to prevent oxidation. The UNIQUE CUTTING-EDGE REFLOW CAPABILITY of nitrogen reflow soldering supports high-volume production. MCB UP Limited utilizes nitrogen to achieve faster production cycles. The reduction in defects minimizes the need for rework. This efficiency results in increased throughput and cost savings. Advanced thermal management in nitrogen reflow ovens contributes to this success.

Quality Control Measures

Quality control remains a priority in PCBA manufacturing. Seegers highlights the role of nitrogen in ensuring reliable solder joints. The inert atmosphere reduces oxidation, leading to cleaner connections. MCB manufacturers implement stringent quality checks. These measures ensure that each product meets industry standards. The use of nitrogen enhances the reliability of SMT Line production.

Surface Mount Technology (SMT) requires precise control over the soldering environment. Nitrogen reflow soldering provides this control. The improved wetting properties result in stronger solder joints. Klein Wassink notes the importance of maintaining high-quality standards. Manufacturers achieve this through continuous monitoring and adjustments. The integration of nitrogen systems supports these efforts.

Nitrogen in reflow soldering offers numerous advantages. The reduction of oxidation enhances solder joint quality. The improved wetting properties lead to stronger connections. Mo Ohady, General Manager at Digicom Electronics, highlights a 50-60% defect reduction with nitrogen use. Nitrogen’s role in achieving high-quality production is undeniable. The industry should consider adopting nitrogen for its proven benefits. The implementation of nitrogen can elevate manufacturing standards. The future of electronics manufacturing relies on such advancements.