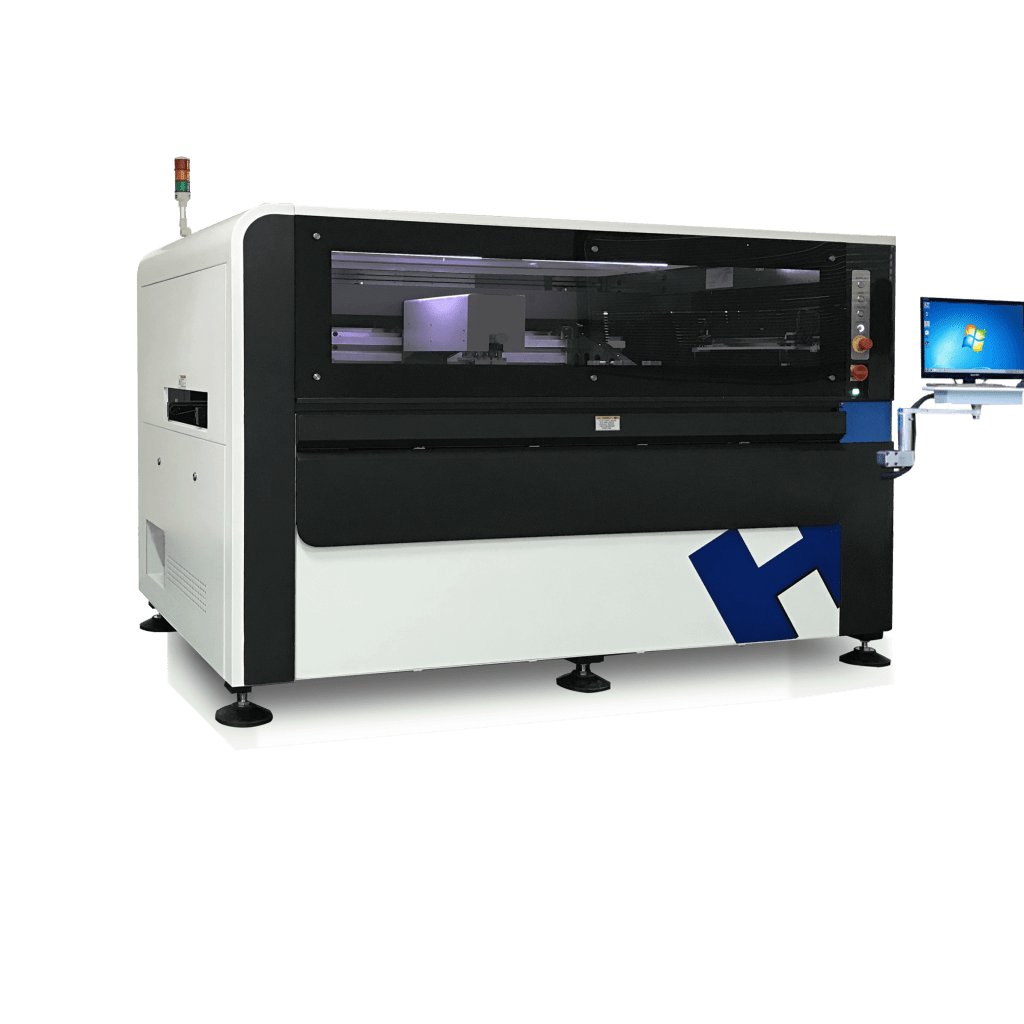

Product Overview

1. Function Overview

CL-1500 is a solder paste printer that meets the needs of ultra-large PCB printing. It has a repeatability of ±12 μm, a printing accuracy of ±25 μm, and a total printing process of 15 seconds (excluding solder paste printing and cleaning). It can process PCB boards from 80mm × 50mm to 1500mm × 510mm, and is suitable for

LED, backlight source and other products.

Basic features of the product:

2.1. Wide PCB size compatibility range, supporting PCBs of different thicknesses from 80mm X 50mm to 1500mm X 510mm; 2.2. High-precision printing resolution;

High positioning accuracy, repeat positioning accuracy ± 12 μm; printing accuracy ± 25 μm; support glue printing;

2.3. Fully automatic control can improve production efficiency, control quality and save costs;

Automatic steel mesh positioning; Automatic PCB correction;

Software pressure closed loop system;

Automatic steel mesh cleaning (dry cleaning, wet cleaning, vacuum cleaning);

2.4. The suspended printing head independently developed by Huanchengxin Company is used to automatically balance the scraper pressure and accurately control the pressure, which can achieve perfect solder paste molding effect;

2.5. The programmable motor controls the separation speed and stroke of the scraper and steel mesh, which can flexibly realize a variety of demoulding methods; 2.6. The multifunctional PCB fixed positioning system makes PCB positioning convenient, fast and accurate;

2.7. Up and down visual positioning system; 2.8. Intelligent image processing system;

2.9, Support 2D, SPI connection, SPC functions;

Solder paste printing range

3.1. Production and processing of SMT components such as resistors, capacitors, inductors, diodes, transistors, etc.:

01005, 0201, 0402, 0603, 0805, 1206 and other specifications and sizes;

3.2, IC: Support SOP, TSOP, TSSOP, QFN and other packages, minimum pitch 0.3mm;

Support BGA, minimum ball diameter (Ball) 0.3mm;

3.3. Printing size: 80mm × 50mm – 1500mm × 510mm; 3.4. PCB specification: thickness 0.6mm – 6mm;

3.5. FPC specifications: thickness less than 0.6mm (with fixture).

Scope of application

Manufacturing of mobile phones, communications, LCD TVs, set-top boxes, home theaters, automotive electronics, medical power equipment, aerospace and other products/equipment, and the production of general electronic products.

Product Specifications

*The following test data is based on an ambient temperature of 25 degrees Celsius and 60% humidity.

| project | parameter | ||

| Repeat Position Accuracy | ±12μm(@6σ Cmk≥2.0) | ||

| Printing Accuracy | ±25μm(@6σ Cmk≥2.0) | ||

| Printing speed/cycle (Cycle Time) | <15s (excluding printing and cleaning time) | ||

| Products Changeover | <5Min | ||

| Screen Stencil Size/Min (X×Y) | 1600mm × 370mm | ||

| Screen Stencil Size/Max ( X×Y ) | 1800mm × 750mm | ||

| Screen Stencil Size/Thickness | 20mm – 40mm | ||

| PCB Printing Size/Minimum (PCB Size/Min) (X×Y) | 80mm × 50mm | ||

| PCB Printing Size/Max (PCB Size/Max) (X×Y) | 1500mm × 510mm | ||

| PCB Size/Thickness | 0.6 – 6mm (a jig is required for diameters below 0.6mm) | ||

| PCB Warpage Ratio | <1% (based on the diagonal length) | ||

| Bottom of Board Size | 15mm (standard configuration) | ||

| Edge of Board Size | 3 mm | ||

| Transport High | 900±20(mm) | ||

| Transport Direction | left-right;right-left;left-left;right-right | ||

| Transport Speed | 100-1500(mm/sec) Programmable control | ||

| PCB positioning

(Board Location) |

Support System | Magnetic ejector pins/edge supports | |

| Clamping System | Elastic side clamp/Z-axis pressure plate/vacuum suction (optional) | ||

| Print head | Programmable electronically controlled print head (standard) | ||

| Scraper Speed | 10 – 200(mm/sec) | ||

| Scraper Pressure | 0 – 15kg software pressure closed loop | ||

| Scraper Angle | 60°/55°/45° (optional) | ||

| Scraper Type | Steel scraper, rubber scraper, other types of scrapers need to be customized | ||

| Stencil Separation Speed | 0.01 – 125 (mm/sec) programmable three-stage control | ||

| Cleaning Method | Dry cleaning, wet cleaning, vacuuming (optional) (programmable in any combination) | ||

| Table Adjustment Range | X:±8mm;Y:±10mm; θ : ±2 ° | ||

| Image fiducial type | Standard geometry fiducials, pads/openings | ||

| Camera System | Digital camera/telecentric coaxial vision system/four-way independent coaxial/ring-shaped LED light source | ||

| CCD(Camera) | 1.3 million pixels, 6.4mm × 4.8mm upper and lower dual fields of view, pixel accuracy 5 μm (optional field of view 10mm × 8mm) | ||

| Air Pressure | 4 – 6Kg/cm2 | ||

| Air Consumption | About 0.007m³/min | ||

| Control Method | PC Control | ||

| Power Supply | AC:220-240V,50/60HZ 1 Φ 3KW,13A | ||

| Machine Dimensions (L×W×H) | 2580 × 1295 × 1520 (mm) (excluding the lighthouse height, see the product external dimensions) | ||

| Machine weight | Approx:1800Kg | ||

| Operation Temperature | -20℃ – +45℃ | ||

| Operation Humidity | 30% – 60% | ||

Machine Configuration

1. Programmable electronic control to adjust the scraper pressure Suspended scraper printing head:

1.1. The scraper pressure can be adjusted by programmable method, and the pressure control is accurate;

1.2. The front and rear scraper pressures are adjusted independently to ensure that there is no pressure imbalance caused by the fatigue deformation of the scraper material, which will cause the difference in front and back printing;

1.3. The programmable motor controls the separation speed and stroke of the scraper and steel mesh;

2. Standard stainless steel scraper, unique design, longer blade life ;

3. Visual alignment system ;

4. Platform UVW automatic correction system ;

5. PCB clamping and supporting device:

5.1, Magnetic ejector pin;

5.2. Flexible clamping device on the PCB side to ensure that the PCB will not bend or deform when clamped; 5.3. Z-axis pressure plate;

5.4, strong vacuum suction (optional);

5.5, Flexible automatic ejector (optional);

6. CNC guide rails adjust the transport width and speed ;

7. Three programmable steel mesh cleaning systems: dry, wet and vacuum, which can be combined arbitrarily ;

8. Industrial control computer, Windows 7 operating system, Chinese/English interface;

9. Intelligent software diagnostic system ;

10. Support 2D, SPI connection, SPC software functions ;

11. Standard SMEMA connection interface.

Disclaimer:

Due to the real-time changes in product batches and production and supply factors, in order to provide accurate product information, specifications and parameters, and product features as much as possible, Huanchengxin may adjust and revise the text descriptions, picture effects and other contents on the above pages in real time to match the actual product performance, specifications, parameters, parts and other information; if there is a need to modify and adjust the above pages, no special notice will be given;