| SM-LⅡ Selective Wave Soldering Technical Parameters | |

| Machine overall | |

| Machine size(mm) | 2950(L)*1650(W)*1675(H) |

| Total machine power/operating power | 20KW/6-8KW |

| power supply | 380V/Single-phase 380V |

| Net weight | 1500Kg |

| Air source requirements | Pressure 0.4-0.6MPa, flow rate 8-12L |

| Nitrogen gas source requirements | Pressure 0.3-0.5MPa, flow rate not less than 5 cubic meters per hour, purity not less than 99.998% |

| Air volume requirements | Above the spray: 800-1000cbm/h; Above the tin furnace: 600-800cbm/h |

| Pallet | |

| Pallet passing size | L260×W 260-L500×W500 mm (Pallet process edge thickness: 3- 10mm) |

| Double nozzle spacing | 165~265 mm |

| Maximum welding area | L500×W500 mm |

| Control and transport | |

| Control System | Industrial computer + controller |

| Shipping width | 50-500 mm |

| Product conveying | Spray and preheating section; chain conveyor; soldering section; roller conveyor |

| PCB transportation direction | Left to right, horizontal transport |

| Maximum component height | 30 mm/100mm on board,30mm of board |

| Transport load-bearing | Less than 10kg |

| Transport height | 900±20mm |

| Spray motion platform | |

| Motion axis | X, Y |

| Motion control | Closed-loop control + servo motor |

| positioning accuracy | ±0.15 mm |

| Rosin management | |

| Flux nozzle | Stainless steel electronic jet mesh*2 |

| Flux containers | Pressure tank, capacity 1L*2 |

| Alcohol volume | Pressure tank, capacity 1L* 1 |

| Warm-up section | |

| Warm-up mode | Warm air warm-up, lower infrared preheating |

| Warm-up power | 13KW |

| Temperature range | Often wet-240℃ |

| Solder motion platform | |

| Motion axis | X, Y, Z |

| Motion control | Closed-loop control + servo motor |

| positioning accuracy | ±0.15 mm |

| Soldering part | |

| Tin tank capacity | 15Kg*2 |

| Tin temperature control | PID |

| Melting time | ≤40 Minutes |

| Maximum tin furnace temperature | 350℃ |

| Tin bath power | 1.2kw x 2 |

| Nozzle material | Low expansion alloy |

| Tin nozzle comes standard | 5pcs x 2 |

| Nitrogen management | |

| Nitrogen heating PID control | 0-350℃ |

| Nitrogen consumption/tin nozzle | 1-2/hour/tin nozzle |

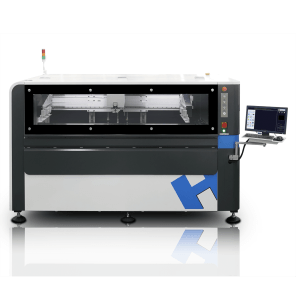

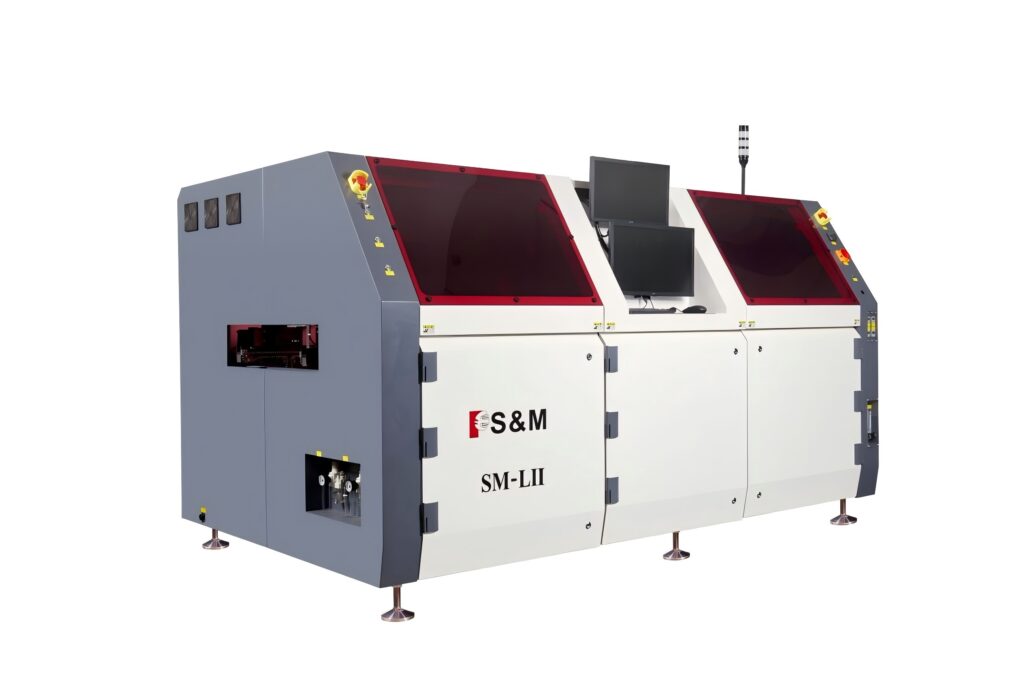

Online Dual Platform Selective Wave Soldering

Product number: SM-LⅡ

- Adopt industrial computer +professional multi-axis motion control card control to achieve high-precision motion control.

- Independently designed control soft ware, which can directly use PCB pictures or GERBER documents for path editing. Course, path starting point, welding movement speed, air travel speed, Z-axis height, peak height, etc. All can be set up on the computer.

- The machine can automatically monitor and record the air intake pressure, transportation speed, preheating temperature, and tin furnace temperature. Including key process parameters, etc. At the same time, the machine has automatic alarms and tips for various common faults Function.

- The machine comes with its own formula function, which can automatically record the expensive setting of various process parameters to facilitate product production. Save and call the pieces; The movement of flux nozzles and solder nozzles is made of aluminum all-in-one with protective precision X and Y flat. The table is driven by a precision ball screw+servo motor, with accurate control, which can achieve high precision of low noise Degree transmission.

- The product delivery is driven by their own independent stepper motors, which are implemented in two stages, and the front section(including flux)The spray section and preheating section) are aluminum guide rail +imported roller chain conveyor structure, rear section (solder Section) Adopts a precision stainless steel roller conveying structure, which can achieve the stability and accuracy of product transmission.

- The product welding process can be displayed in real time, can be transmitted to computer software through the camera, and can be welded. Take photos, record videos and save them.

- The overall frame adopts a steel welded structure, and the machine is stable and durable and not easy to deform.

Specifications

Product Features