Surface Mount Technology (SMT) revolutionizes electronics manufacturing. SMT allows for the placement of components directly onto the surface of printed circuit boards. This method enhances production efficiency. The global SMT market reached a valuation of USD 25.28 billion in 2024. Experts anticipate significant growth, with a projected CAGR of 13.65% from 2024 to 2031. Machinery plays a crucial role in this process. Equipment like pick and place machines, reflow ovens, and solder paste printers automate assembly. These advancements contribute to the widespread adoption of SMT across various industries.

Understanding Surface Mount Technology (SMT)

Definition and History of SMT

Surface Mount Technology (SMT) represents a pivotal advancement in electronics manufacturing. Engineers developed SMT to mount electronic components directly onto the surface of printed circuit boards (PCBs). This method replaced the older through-hole technology, which required drilling holes into PCBs for component leads.

Evolution of SMT in Electronics

The evolution of SMT began in the 1960s. Manufacturers sought methods to increase the density of components on PCBs. The introduction of SMT allowed for smaller and more complex electronic devices. By the 1980s, SMT had become the standard in electronics manufacturing. The technology enabled the placement of tiny surface mount components, contributing to the trend of miniaturization in electronic devices.

Key Milestones in SMT Development

Several key milestones marked the development of SMT. In the 1970s, the first commercial SMT components appeared. By the 1980s, automated pick and place machines revolutionized the assembly process. These machines ensured precise component mounting and soldering on circuit boards. The 1990s saw further advancements with the introduction of more sophisticated inspection and testing equipment. Today, SMT plays a critical role in modern automotive manufacturing and other industries.

Core Principles of SMT

Understanding the core principles of SMT involves grasping basic concepts and techniques. SMT relies on automated machinery to place components accurately on PCBs. The process begins with a stencil printer applying solder paste to the board. A pick and place machine then positions components onto the paste. Finally, a reflow oven heats the board, melting the solder and securing the components.

Basic Concepts and Techniques

Several basic concepts and techniques define SMT. Engineers use solder paste to attach components to PCBs. Automated machines handle the placement of components, ensuring precision and speed. Reflow ovens play a crucial role by heating the solder paste to form permanent connections. SMT allows for the manufacturing of more passive components due to specific dimensions.

Advantages Over Traditional Through-Hole Technology

SMT offers several advantages over traditional through-hole technology. The method supports higher component density on PCBs, leading to smaller devices. SMT enhances production efficiency by automating the assembly process. The technology also improves reliability by reducing the number of mechanical connections. SMT has become essential in producing modern electronic devices across various industries.

Key Machinery in SMT

Pick and Place Machines

Functionality and Operation

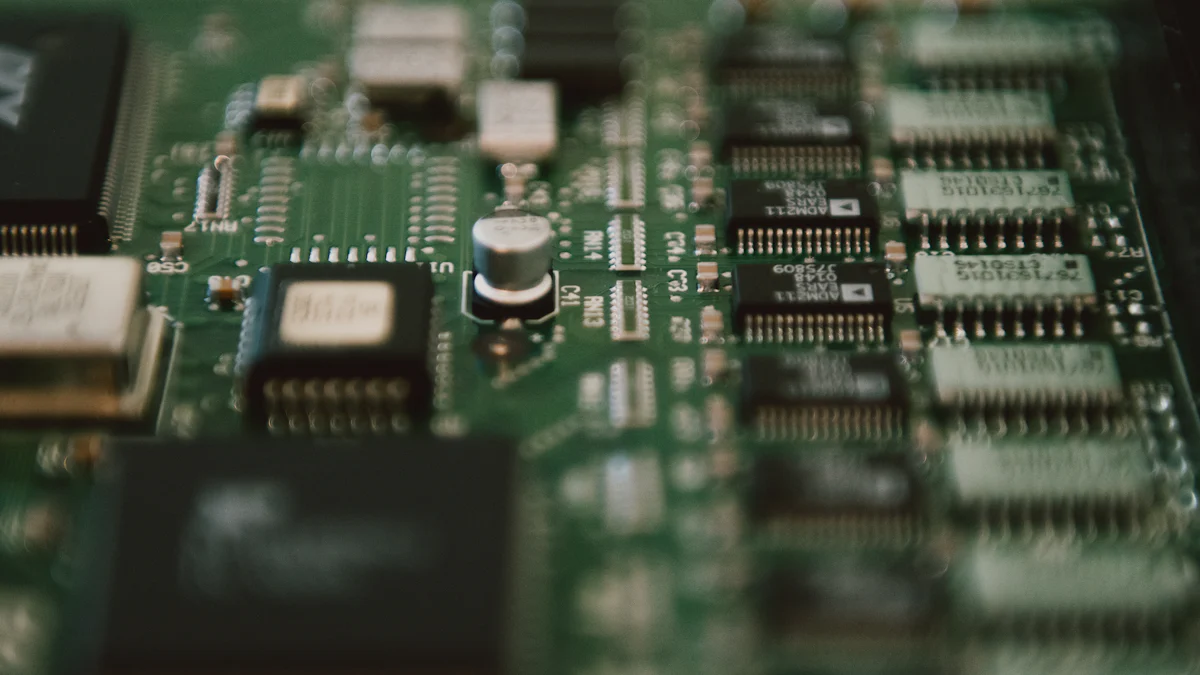

Pick and place machines serve as essential components in the Surface Mount Technology (SMT) assembly line. These machines retrieve electronic components from trays, reels, or tubes. The machines then accurately position these components onto solder paste on printed circuit boards (PCBs). This process ensures precise placement, which is crucial for the functionality of electronic devices. Pick and place machines operate with high speed and precision. This capability allows them to handle a wide range of electronic components, including capacitors, resistors, and integrated circuits.

Types of Pick and Place Machines

Different types of pick and place machines exist to cater to various manufacturing needs. Some machines focus on high-speed operations, while others prioritize precision. High-speed machines excel in mass production environments. Precision machines are ideal for complex assemblies requiring meticulous component placement. Manufacturers often use a combination of these machines to optimize production efficiency and quality.

S&M Reflow Ovens

Purpose and Process

Reflow soldering is to melt the solder paste pre-coated on the pad by heating, so as to realize the electrical interconnection between the pin soldering ends of the electronic components pre-mounted on the pad and the pads on the PCB, so as to achieve the purpose of soldering the electronic components on the PCB. Reflow soldering is generally divided into preheating zone, heating zone, soldering zone and cooling zone.

Different Types of Reflow Ovens

The S&M reflow oven is mainly divided into the VS series lead-free nitrogen hot air reflow oven and the VS series lead-free air hot air reflow oven. Both use lead-free processes, making them more environmentally friendly.

Solder Paste Printers

Role in SMT Process

Solder paste printers initiate the SMT assembly process. These printers apply solder paste onto PCBs through stencils. The solder paste serves as an adhesive for components during placement. Accurate application of solder paste is crucial for successful soldering in subsequent steps. Solder paste printers ensure consistent paste deposition, which enhances assembly quality.

Variations and Specifications

Solder paste printers come in various configurations to meet diverse manufacturing requirements. Some printers offer manual operation for small-scale production. Automated printers suit high-volume manufacturing environments. Specifications such as printing speed, accuracy, and stencil size vary among models. Manufacturers select printers based on their specific production needs and desired output quality.

Inspection and Testing Equipment

Importance of Quality Control

Quality control ensures the reliability and performance of electronic devices. Inspection equipment identifies defects in components and assemblies. This process prevents faulty products from reaching consumers. Manufacturers rely on quality control to maintain high standards. Consistent quality control enhances brand reputation and customer satisfaction.

Types of Inspection Equipment

Inspection equipment varies to suit different manufacturing needs. Automated Optical Inspection (AOI) machines use cameras to detect defects. AOI machines identify missing components and soldering errors. X-ray inspection systems examine hidden solder joints. These systems reveal internal defects not visible to the naked eye. In-Circuit Testers (ICT) check electrical performance. ICT verifies connections and component functionality. Each type of equipment plays a crucial role in ensuring product quality.

S&M Peripheral Equipment

Loader & Unloader

Loaders and unloaders streamline the SMT assembly process. Loaders feed printed circuit boards (PCBs) into the production line. Unloaders remove completed PCBs from the line. These machines automate the handling of PCBs. Automation reduces manual labor and increases efficiency. Loaders and unloaders support continuous production flow.

PCB Buffer and Conveyors

PCB buffers and conveyors manage the movement of PCBs. Buffers temporarily store PCBs during production. This storage prevents bottlenecks in the assembly line. Conveyors transport PCBs between different stages. Smooth transportation enhances production speed and efficiency. Buffers and conveyors contribute to a seamless SMT process.

Practical Applications and Advantages of SMT

Applications in Various Industries

Consumer Electronics

Surface Mount Technology (SMT) plays a crucial role in consumer electronics. Manufacturers use SMT to produce smartphones, tablets, and laptops. The technology enables the creation of compact and lightweight devices. SMT allows for high-density component placement on printed circuit boards (PCBs). This capability results in smaller and more efficient electronic products. Consumers benefit from advanced features and improved performance.

Automotive Industry

The automotive industry relies heavily on SMT. Electronic control units (ECUs) in vehicles use SMT for assembly. These units manage essential functions like engine control and safety systems. SMT enhances the reliability of automotive electronics. The technology supports the miniaturization of components. Smaller components allow for more sophisticated vehicle designs. Automakers achieve better fuel efficiency and reduced emissions through SMT.

Benefits of Using SMT

Cost-Effectiveness

SMT offers significant cost advantages. Automated machinery reduces labor costs in manufacturing. High-speed production lines increase output and efficiency. SMT minimizes material waste during assembly. Manufacturers save on raw materials and production expenses. The cost-effectiveness of SMT makes it attractive for large-scale production.

Enhanced Performance and Reliability

SMT improves the performance and reliability of electronic devices. The technology ensures precise component placement on PCBs. Accurate placement enhances electrical connections and device functionality. SMT inspection machines detect defects early in the process. High-resolution cameras and advanced algorithms identify flaws. Manufacturers achieve consistent quality and reduce product failures. Reliable electronics enhance user satisfaction and brand reputation.

Surface Mount Technology (SMT) has transformed electronics manufacturing. SMT machinery, such as pick and place machines and reflow ovens, ensures efficient production. The growing demand for consumer electronics and automotive advancements highlights SMT’s significance. The Asia Pacific region leads in SMT technology due to its strong electronics manufacturing base. Future trends indicate increased miniaturization and integration of components. SMT will continue to drive innovation in industries like automotive and consumer electronics. The impact of SMT on modern electronics manufacturing remains profound and far-reaching.