Selective wave soldering is a device in the field of PCB through-hole soldering. It achieves selective and precise soldering of specific components by precisely controlling soldering parameters such as temperature, time, and wave crest height. Due to its unique advantages in soldering, it has gradually become popular in the field of PCB through-hole soldering in recent years.

Key Takeaways

- Selective wave soldering is a targeted soldering technique that enhances precision by soldering specific areas of a PCB, protecting sensitive components from heat damage.

- The process involves three critical steps: flux application, preheating, and soldering, each essential for achieving high-quality solder joints.

- Using advanced wave solder machines with features like high-precision control and automated monitoring can significantly improve soldering efficiency and reduce operational costs.

- Regular maintenance, including cleaning, inspection, and calibration, is vital for ensuring the longevity and performance of selective wave soldering equipment.

- Technical support from manufacturers can optimize soldering processes, assist with troubleshooting, and provide training to enhance operational skills.

- Selective wave soldering is particularly beneficial for industries like aerospace and telecommunications, where reliability and precision are paramount.

- By adopting selective wave soldering, manufacturers can confidently meet the demands of modern electronics with efficient and accurate assembly of complex designs.

Definition of selective wave soldering

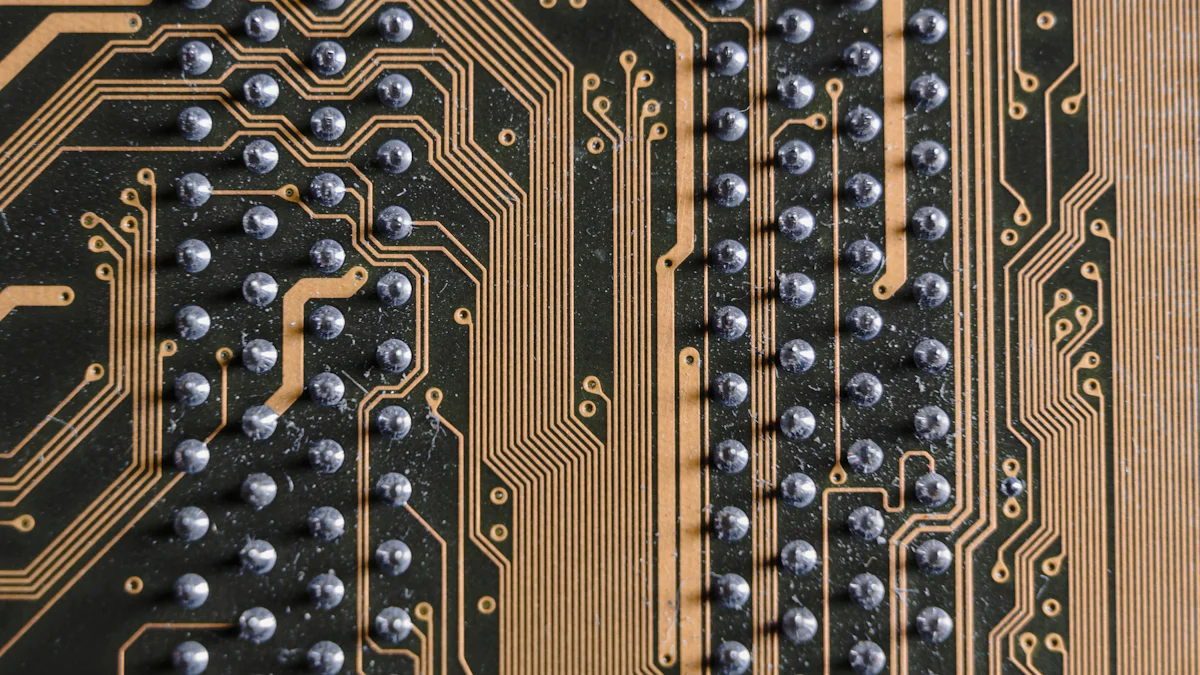

Selective wave soldering is a specialized soldering process designed to meet the demands of modern electronics manufacturing. Unlike traditional wave soldering, this technique focuses on soldering specific areas of a printed circuit board (PCB) while leaving other components untouched. You can think of it as a targeted approach that ensures precision and minimizes the risk of heat damage to sensitive parts.

Equipment features

The equipment used in selective wave soldering is engineered for precision and efficiency. A wave solder machine designed for this process incorporates advanced features to ensure consistent and reliable results. Here are some key features you can expect:

- High-precision soldering control systems: These systems allow you to adjust parameters like temperature, time, and flow rate for each solder joint. This level of control ensures optimal soldering quality for various components.

- Advanced transfer mechanisms: These mechanisms enable smooth and accurate movement of the PCB during the soldering process, reducing errors and enhancing efficiency.

- Multi-wave technology: This feature guarantees a stable and reproducible soldering process, even for complex PCB designs. It also shortens cycle times, making the process more efficient.

- Automated programming and monitoring: Modern machines come with software that lets you set up programs easily. You can use PCB images or GERBER files to define soldering paths. The system also monitors critical parameters like air pressure, preheating temperature, and soldering speed, ensuring consistent performance.

- Durable construction: High-quality materials like aluminum and steel are used to build these machines. This ensures durability and stability, even under demanding manufacturing conditions.

A wave solder machine equipped with these features not only enhances the soldering process but also reduces operational costs. By automating key steps and providing precise control, these machines help you achieve superior results with minimal effort.

The Selective Wave Soldering Process

Operation process

Selective wave soldering involves a series of precise steps to ensure high-quality results. Each step plays a vital role in achieving accurate and reliable soldering for your PCB components.

Flux application

The process begins with flux application. Flux prepares the soldering area by cleaning it and preventing oxidation during the soldering process. You apply the flux only to the specific areas that require soldering. This targeted approach ensures that the surrounding components remain unaffected. Modern selective wave soldering machines often use a high-precision spraying system to apply flux evenly and accurately.

Preheating

After applying the flux, preheating comes next. Preheating raises the temperature of the PCB to an optimal level, ensuring that the solder flows smoothly during the next step. This stage also helps to reduce thermal shock, which can damage sensitive components. Many advanced machines use a combination of upper hot air and lower infrared heating to achieve uniform preheating. This design ensures that your PCB is ready for the soldering phase without compromising its integrity.

Soldering with a selective wave

The final step is soldering with a selective wave. A wave solder machine creates a controlled wave of molten solder, which is directed precisely to the designated areas of the PCB. The machine uses a solder nozzle to apply the solder with pinpoint accuracy, ensuring that only the intended components are soldered. This method minimizes the risk of heat damage to nearby parts and guarantees a strong, reliable connection. The use of nitrogen protection during this step further enhances the quality of the soldering by preventing oxidation.

Application scenarios

Selective wave soldering is ideal for various applications, especially in industries requiring precision and reliability. You will find this process particularly useful for through-hole components, which are common in high-end electronic products. It is also well-suited for densely populated PCBs, where traditional soldering methods may struggle to achieve the same level of accuracy.

This technique has become increasingly popular since the rise of surface-mount devices (SMDs) in the early 2000s. As SMD components gained market share, manufacturers faced challenges in manual soldering. Selective wave soldering machines emerged as a solution, offering a more efficient and precise alternative. Today, industries such as aerospace, automotive, and telecommunications rely on this process to meet their demanding manufacturing standards.

By using a wave solder machine equipped with advanced features, you can achieve consistent results across a wide range of PCB designs. Whether you are working with complex layouts or delicate components, selective wave soldering provides the control and precision you need to succeed.

Maintenance Precautions of Selective Wave SolderingProper maintenance ensures the longevity and efficiency of your selective wave soldering equipment. Neglecting maintenance can lead to inconsistent soldering results and equipment malfunctions. By following a structured approach, you can maintain optimal performance and reduce downtime.

1. Regular Cleaning of Components

Clean the machine’s critical components, such as flux nozzles, solder nozzles, and conveyor chains, regularly. Residue buildup on these parts can affect the precision of the soldering process. Use appropriate cleaning agents to remove flux residues and solder splashes. Keeping these components clean ensures smooth operation and accurate solder application.

2. Inspection of Moving Parts

Inspect moving parts like conveyor belts, pallets, and ball screws frequently. Look for signs of wear or misalignment. Worn-out parts can disrupt the PCB’s movement during soldering, leading to errors. Replace damaged components immediately to maintain the machine’s accuracy and reliability.

3. Monitoring Temperature Settings

Check the preheating and soldering temperatures daily. Incorrect temperature settings can compromise solder quality and damage sensitive components. Use the machine’s monitoring system to verify that the preheating and soldering zones maintain consistent temperatures. Adjust settings as needed to match the requirements of your PCB design.

4. Lubrication of Mechanical Components

Apply lubrication to mechanical parts like servo motors and precision ball screws. Proper lubrication reduces friction and prevents wear, ensuring smooth operation. Use manufacturer-recommended lubricants to avoid damaging the equipment.

5. Scheduled Preventative Maintenance

Develop a maintenance schedule that includes all critical tasks. Focus on areas like flux application systems, solder pots, and nitrogen supply lines. Scheduled maintenance minimizes unexpected breakdowns and keeps the machine running efficiently. According to “Scheduled Preventative Maintenance for Wave Soldering Machines”, regular checks of fingers, pallets, and conveyor chains are essential for meeting production quotas.

6. Calibration of Sensors and Systems

Calibrate sensors and control systems periodically. Accurate calibration ensures that parameters like air pressure, solder flow, and Z-axis height remain within optimal ranges. This step is crucial for maintaining the precision of the soldering process.

7. Safety Checks

Perform safety checks to identify potential hazards. Inspect alarms, emergency stop buttons, and protective covers. Functional safety features protect both the operator and the equipment during operation.

8. Documentation of Maintenance Activities

Keep detailed records of all maintenance activities. Documenting tasks like cleaning, inspections, and part replacements helps you track the machine’s condition over time. These records also assist in diagnosing recurring issues and planning future maintenance.

By adhering to these maintenance precautions, you can ensure that your selective wave soldering machine operates at peak performance. Regular upkeep not only extends the equipment’s lifespan but also guarantees consistent and high-quality soldering results.

Equipment technical support

Technical support plays a vital role in ensuring the smooth operation and longevity of your selective wave soldering equipment. Manufacturers and suppliers often provide comprehensive assistance to help you optimize your soldering processes and achieve consistent results. Here’s how technical support can enhance your experience with a wave solder machine:

1. Expert Guidance for Process Optimization

Many companies, such as Indium Corporation, offer access to experienced technical teams. These experts assist you in fine-tuning your soldering parameters, including flux application, preheating, and soldering temperatures. Their recommendations help you maximize yield and minimize production costs. By leveraging their expertise, you can address challenges like oxidation, uneven solder flow, or thermal damage to components.

2. Integration with Manufacturing Systems

Modern selective wave soldering machines, like those from SMT Machine, are designed for seamless integration into your production line. Technical support teams guide you in connecting your equipment with assembly stands, peripheral devices, and traceability systems. This integration ensures streamlined operations and comprehensive process control, enhancing overall efficiency.

3. Troubleshooting and Maintenance Assistance

Technical support teams provide valuable assistance in diagnosing and resolving equipment issues. They help you identify the root cause of problems, whether it’s related to flux nozzles, solder pots, or conveyor mechanisms. Regular consultations with these experts ensure that your machine operates at peak performance, reducing downtime and maintaining soldering quality.

4. Training and Knowledge Sharing

Many manufacturers offer training programs to help you and your team understand the intricacies of selective wave soldering. These sessions cover topics like equipment setup, parameter adjustments, and maintenance best practices. By participating in these programs, you gain the skills needed to operate your wave solder machine effectively and confidently.

5. Access to Advanced Features and Updates

Suppliers often provide updates and upgrades for their equipment, ensuring that you stay ahead in a competitive market. For instance, SMT Factory highlights the high level of technological maturity in modern selective wave soldering machines. Technical support teams help you implement these advancements, such as multi-wave technology or nitrogen protection, to enhance your soldering process.

By utilizing the technical support services offered by manufacturers, you can unlock the full potential of your selective wave soldering equipment. These services not only improve your production efficiency but also ensure consistent, high-quality results for your PCBs.

Selective wave soldering offers a precise and efficient solution for modern PCB manufacturing. It focuses on soldering specific areas, ensuring minimal heat impact on surrounding components. The process, involving flux application, preheating, and targeted soldering, delivers high-quality results. You gain advantages like flexibility, precision, and suitability for complex or high-performance boards. This method excels in industries requiring reliable connections, such as aerospace and telecommunications. By adopting selective wave soldering, you enable accurate assembly of intricate designs, meeting the demands of advanced electronics manufacturing with confidence and efficiency.